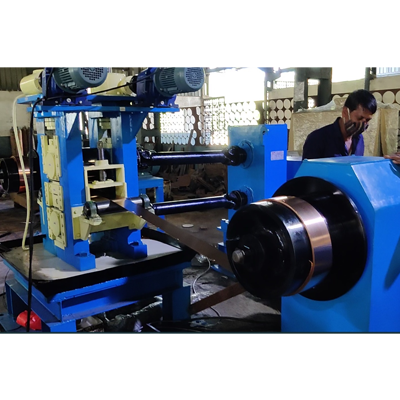

4 Hi Cold Rolling Mills

The 4Hi Cold Rolling Mills are used for rolling of coils, sheets and plates of all types of metals and alloys like Stainless Steel, Mild Steel, Brass, Copper, Cupro-Nickel, Aluminum etc. We have manufactured more than 400 such rolling mills running successfully all over India and abroad in countries like Brazil, Turkey, Malaysia, Nigeria, Kenya, Zambia, Tanzania etc. We can manufacture mills upto 800 mm width for harder metals like Stainless Steel and upto 1800 mm width for softer metals like Copper/ Brass/ Aluminum etc. Optimum design and raw materials machined to high accuracy help us achieve close thickness tolerance, flatness and high surface finish on rolled products.

| Product Specification of 4hi – Cold Rolling Mill | |

| Machine Type | 4HI cold rolling mill |

| Mil Type | Reversible/Non Reversible |

| Pressing Device | Manual/Mechanical Screw down/ Hydraulic AGC |

| Input Raw Material | Ferrous and Non-Ferrous Metal |

| Rolled shape Material | Coils, Foils, Strips, sheet |

| Input thickness | 2.0mm-4.0mm |

| Input width | 50mm-1250mm |

| Production capacity | 15-30 tonnes/day |

| Coiler Weight Max* | 1000-5,000kgs |

| Mill speed Max* | 10-400MPM |

| Finished Output Thickness / Width | 0.10mm-0.50mm |

| Maximum inner/outer diameter of the coil | 300mm-350mm-508mm/1500mm |

| Maximum rolling force | 80-400 tonnes |

| Depression type | Mechanical Screw Down / Manual / Servo / Hydraulic AGC |

| Transmission mode | work roll/Backup Roll transmission |

| Roll bearing lubrication method | Grease lubrication/ Air oil Lubrication |

| Rack section | 200 x 350 |

| Electronic control | Siemens/Schneider / L & T |

| Reducer Gear box | Elecon/shanti / Self made |

| Motor | Siemens/BBL/ABB |

| Total installed capacity | As per machine specification |

Features –

- - Heavily reinforced Stand Housings machined to closest tolerances (Window Size within 0.04 mm)

- - Back Up Rolls made of forged alloy steel having hardness in range of 54-58 HRC

- - Back Up Roll running on Spherical Roller Bearings fitted in C-45 grade steel cast housings

- - Work Rolls made of forged Alloy steel having high hardness of 62+ HRC as required

- - Motorised worm geared Screw Down with Bronze Nut & Buttress threaded Alloy Steel Screw.

- - Extra heavy duty Gear Box & Pinion Stand with hardened output shafts

- - Roll removal trolley system for easy replacement of Rolls

- - AGC for accurate thickness control (optional)

Application –

- - Rolling mills

- - Metal industry