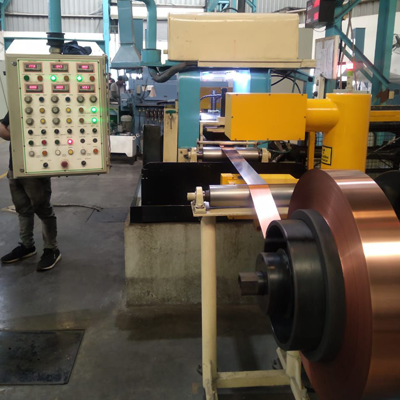

We produce the premium nature of Cold Rolling Mills for Stainless Steel which gives great power and resilience to stainless steel products. This machine helps in improving the surface finish and tensile strength of the stainless steel coils, sheet and strips. Stainless steel formed in cold rolling mills are annealed and pickled before it is processes through skin pass mill, to ensure a smoother surface. Further, we give a uniform scratch finish by polishing with abrasive belts. We offer profiles that offers the most precise and reasonable solution for our clients desired components.

| Product Specification of 6 – Cold Rolling Mill | |

| Machine Type | 6hi cold rolling mill |

| Mil Type | Reversible/Non Reversible |

| Pressing Device | Manual/Mechanical Screw down/ Hydraulic AGC |

| Input Raw Material | Ferrous and Non-Ferrous Metal |

| Rolled shape Material | Coils, Foils, Strips, sheet |

| Input thickness | 2.0mm-4.0mm |

| Input width | 50mm-1250mm |

| Production capacity | 15-30 tonnes/day |

| Coiler Weight Max* | 1000-5,000kgs |

| Mill speed Max* | 10-400MPM |

| Finished Output Thickness/Width | 0.020mm-0.10mm |

| Maximum inner/outer diameter of the coil | 300mm-350mm-508mm/1500mm |

| Maximum rolling force | 80-400 tonnes |

| Depression type | Mechanical Screw Down / Manual/Servo/ Hydraulic AGC |

| Transmission mode | Backup Roll transmission |

| Roll bearing lubrication method | Grease lubrication/ Air oil Lubrication |

| Rack section | 200 x 350 |

| Electronic control | Siemens/Schneider / L & T |

| Reducer Gear box | Elecon/shanti / Self made |

| Motor | Siemens/BBL/ABB |

| Total installed capacity | As per machine specification |

| Unit size | As per machine specification(LxWxH) |

Features –

- - Quality approved stainless steel

- - Scratch resistant

- - High productivity and output

- - Firm built

- - Minimal operating cost

- - Accurate performance

- - Nominal operating cost

Application –

- - Rolling mills

- - Copper tape

- - Copper foil 0.020mm

- - Electrical components